The months seem to fly by over the summer but with that had brought great progress on our Urie S15 No 499. Below, for the engineering fans and those interested in what is involved in restoring a steam engine, is the latest engineering report. It is of course a bare bones report as always but if anything shows the work put in buy the team, most who are volunteers giving up their time to get our two Urie S15s running together.

Work undertaken included:

- Old rubber blocks removed from loco spring hanger mounting blocks

- New plates bored out for the above

- Castings will need replacing, we’re looking to fabricate the new ones

- Rear tender chassis section repacked ready for riveting

- A number of holes on rear tender section countersunk ready for riveting

- New oil fillers underway for bogie axle boxes

- Various pipe sections painted

- Front bogie cross stretcher outer bracket assemblies cleaned down, primed and undercoated

- Front tender bogie pivot plate prepared for riveting the stop blocks

- Both stop blocks prep’d and riveted to the front bogie pivot plate. This was done with the aid of Will Stratford as one of his new ‘Working On It’ videos for the railway. Weather was awful at times but dry at others so we managed the whole shoot, Will’s hoping he might get it out this week, if not it’ll be another couple of weeks as he’s away on hols soon.

- Stop block rivets ground flush

- New plate to the end of the floor bearer on the rear tender chassis section l/h side was riveted to the support angles

- Top plate at the rear of the tender riveted to the supporting angle, l/h side only.

- Great to see Steve G again bringing gifts from his ‘homework’. Newly manufactured are:

• 4 x bogie compensating beam oil pot lids

• 4 x locking plates for bogie spring hangers

- Start made to build up the ‘pads’ on boiler 799 with weld

- Preliminary identification of holes to be repaired in copper firebox sidesheet, r/h side

- Matt Oakley (ex boiler shop staff) is joining us as a volunteer, his first task is to cut out the remaining wasted lap in the firebox and form a replacement from new copper

- Further painting of loco pipework

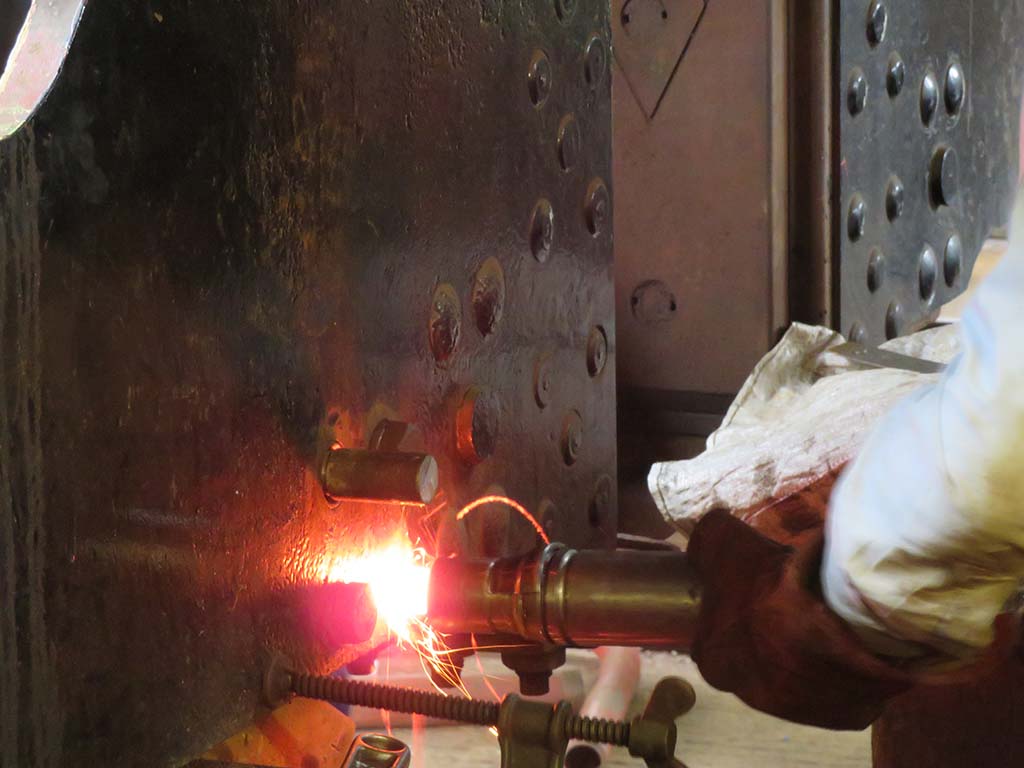

- The holes for the spring hangers in the bogie compensating beams were in a very bad condition, way beyond the normal build up with weld and drill. One of our volunteers, Kev Hall, is a plant engineer and recently invested in a boring bar. As a contracted job, and with assistance from Barry (who I believe was NOT wearing a tutu!), the guys spent 2 days last week working on the holes which are now in much better shape. Thanks Kev!

- 2 axleboxes are being ‘blued’ in on one of the bogie axles so this part of the restoration is moving apace

- Bogie spring hanger pins finish machined

- Cotters and keys manufactured for above

- Remaining 2 bogie axleboxes being fitted

- Rear section of tender chassis repacked and slewed in readiness for riveting on r/h side (nearest the containers)

- Millscale/rust cleaned of underside face of front tender bogie pivot plate

- More painting of loco pipework

- Further repairs with weld build-up to boiler pad mountings

- Pad mounting holes countersunk ready to be filled with weld and re-drilled.

- 2 holes filled

- Copper firebox sidesheet stay holes marked for repair now countersunk

- Last (36 ish) crown stay stubs pilot drilled

- 2 new bushes fitted to bogie compensating beam